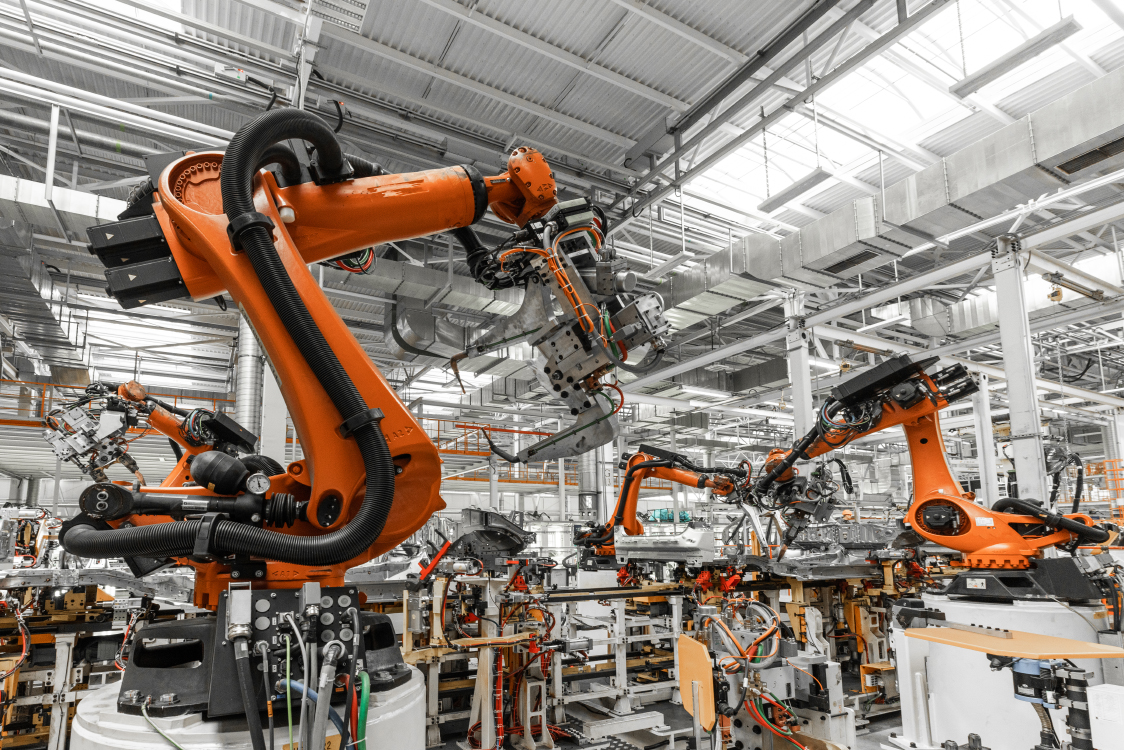

Quality control refers to the activities undertaken to ensure that products are manufactured to meet certain standards and that defects are identified before they result in a product failure or safety hazard. Given the importance of quality control in manufacturing, it’s no surprise that businesses are turning to AI vision systems to improve their quality control processes.

AI vision systems refer to a set of technologies that use machine learning algorithms and computer vision techniques to analyze images and videos and make automated decisions based on that analysis.

Let’s break down how AI vision systems can benefit your business.

AI vision systems use advanced algorithms and computer vision technology to perform quality control inspections accurately. These systems can detect even the slightest defects or deviations from the standard, ensuring that only high-quality products leave the manufacturing facility.

By scanning products at a much faster rate than human inspectors, AI vision systems enable faster detection of defects. This way, defective products can be identified and removed from the production line right away.

Eliminating the risk of human error and biases in quality control inspections, AI vision systems ensure consistent and unbiased assessments. Unlike humans, AI systems do not get tired, distracted, or influenced by personal biases.

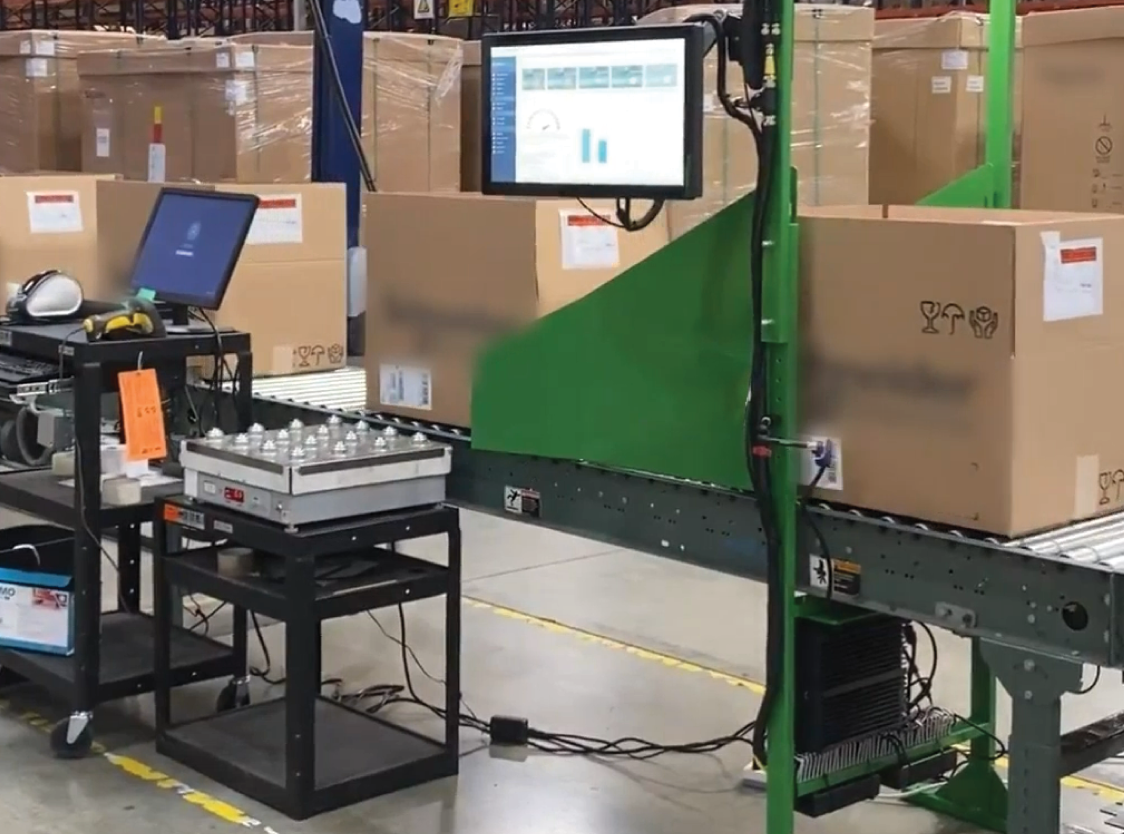

Providing real-time data analytics and reporting on product quality, AI vision systems offer valuable insights into the production process. Manufacturers can utilize this information to optimize manufacturing processes, improve product quality, and reduce waste.

Monitoring the manufacturing environment for potential safety hazards, such as machine malfunctions or workplace accidents, AI vision systems contribute to enhanced safety and risk management in manufacturing facilities. They detect and address these issues in real time, promoting a safer work environment.

Check out all the hardware we use for our systems!

Several AI vision systems are used in manufacturing, including machine vision systems, deep learning systems, and neural networks. These systems use advanced computer vision technology to analyze images and detect product defects.

Using machine learning algorithms and computer vision techniques, AI vision systems analyze images of products to identify and recognize patterns. These techniques enable the system to improve over time as it receives more data, allowing for accurate defect detection.

The training process of AI vision systems doesn’t always require large datasets. By providing the system with labeled images indicating defective products, it can learn to identify defects and anomalies. Additionally, these AI models can be customized to cater to specific manufacturing needs, such as detecting defects in a particular product category.

Manufacturers can seamlessly integrate AI vision systems with their existing quality control processes and equipment. This integration enables the reduction of manual inspections and enhances overall product quality. By leveraging AI technology, manufacturers can streamline their operations and improve efficiency.

Don’t miss out on our technology – here is our pricing list.

Reducing defects in manufacturing is a top priority for any production line. AI vision technology helps achieve this goal.

Surface inspection systems have helped identify defects, capture images, and store accompanying metadata. Defects are classified based on the type and assigned a corresponding grade, allowing manufacturers to distinguish between defects. This information stops production only when a certain number of specific defects have occurred, improving efficiency.

An AI vision system with a Dalsa Genie Nano camera is being used in a production line. The system captures high-resolution images to build a complete 3D model of components and their connector pins. This enables the system to detect faulty connector pins on circuitry.

3D vision inspection has a wide range of applications, with one of the most common use cases being in automobile production. Given that electrical faults make up a significant proportion of automobile failures, 3D scans of connector pins can help manufacturers reduce costs, decrease the likelihood of shipping faulty electrical components, and improve driver safety.

Investing in AI vision systems can be expensive, and we recommend that businesses conduct a cost-benefit analysis to help decide if the investment is worth it. The advantages of AI vision systems include improved accuracy in detecting defects, reduced human error and bias, enhanced production efficiency, and increased product quality and customer satisfaction.

Companies must weigh these benefits against the costs of implementing the system, including hardware, software, and integration costs.

AI vision systems often must integrate with existing systems and equipment to work effectively. Businesses must consider whether their current systems and equipment can be integrated with AI vision systems or if they require new hardware and software.

Implementing AI vision systems requires staff training and adoption. Your employees need training to use the system effectively.

AI vision systems gather and evaluate sensitive data, so businesses must ensure their systems are secure and comply with privacy regulations. This includes ensuring that data is encrypted during transmission and storage, limiting access to data, and implementing access controls.

Lastly, AI vision systems are continuously evolving, and businesses need to consider future developments when investing in the technology. This includes developments in machine learning algorithms, improvements in hardware and software, and new applications for AI vision systems in manufacturing quality control

Find out why businesses trust us for their quality control needs.

Moreover, AI vision systems bring significant benefits to quality control in manufacturing, including increased accuracy and precision, faster defect detection, and reduced human error and bias. With real-time data analytics and reporting integration, these systems provide manufacturers with valuable insights that help optimize production processes.

With continued technological advancements, the future outlook for using AI vision systems in manufacturing quality control is optimistic. As more manufacturers adopt these systems, we can expect to see even greater improvements in efficiency.

At Flexible Vision, our executive team comes from 20+ years in the automation and vision world and has experienced the challenges of traditional vision systems on production lines. With an understanding of the industry’s needs, we’re here to help you make quality control a breeze.

Schedule a live demo with us to learn more.

AI vision systems improve quality control in manufacturing by increasing inspection accuracy, reducing human error and biases, providing real-time analytics and reporting, and enhancing safety and risk management.

Commonly used AI vision systems in manufacturing include machine learning algorithms and computer vision techniques, 2D and 3D imaging, and customizable systems that can be integrated with existing quality control processes and equipment.

AI vision systems help manufacturers reduce costs and improve productivity by minimizing waste and rework, optimizing production processes, enhancing safety and risk management, and identifying and addressing issues before they become more serious.

One potential drawback is the initial cost of implementing these systems, which may be high for smaller businesses. There is also the potential for false positives or negatives, leading to wasted time and resources or missed defects. However, these limitations are easily mitigated through proper training and customization of the AI models and regular testing and evaluation of the system’s performance.

Got more questions? Explore our FAQs.