In the fast-paced world of food and beverage production, maintaining impeccable quality is non-negotiable. Consumers expect perfection, and even minor flaws can lead to costly recalls and damage brand reputation. Just as a seamless user experience (UX) is crucial for digital products, flawless product integrity is paramount for physical goods. This is where advanced vision systems, like those offered by Flexible Vision, step in to revolutionize quality control.

Why Precision Matters in Food & Beverage Production

Similar to how a well-crafted UX enhances user satisfaction and loyalty, consistent product quality builds customer trust and brand loyalty. In a competitive market, even small defects can erode that trust. Here’s how meticulous inspection contributes to success:

Key Inspection Points in Food & Beverage Production

Just as UX focuses on usability, accessibility, and emotional design, food and beverage production demands attention to specific critical inspection areas:

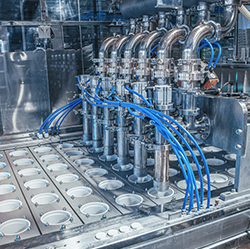

The Power of Advanced Visual AI Systems

Just as AI is revolutionizing digital accessibility, it’s transforming quality control in food and beverage production.

Personalized Inspection Through Software

Just as personalized software enhances UX, customized vision systems optimize production efficiency.

Ensuring Accuracy with Visual AI

Just as visual AI enhances digital accessibility, it ensures accuracy in product inspections.

Bottom Line

Advanced visual AI systems are transforming food and beverage production by ensuring unparalleled quality control. From meticulous bottle and heat seal inspections to precise label verification, these systems provide the accuracy and efficiency needed to meet today’s demanding standards. Just as a strong UX is essential for digital success, flawless product integrity is crucial for building a successful food and beverage brand.

Flexible Vision offers end-to-end factory solutions tailored to your specific needs. Contact us today to learn how our advanced vision systems can help you achieve production excellence.

Visual AI refers to artificial intelligence technologies that process and interpret visual information from the environment. In digital interfaces, it’s used for tasks like image recognition, enhancing user experience, and providing accessibility features.

AI enhances user experience by personalizing interfaces, predicting user needs, and providing more efficient navigation. It uses machine learning to analyze user behavior and tailor digital experiences to individual preferences, making applications more user-friendly.

AI automates and streamlines the data collection and analysis process. It can gather data from various sources, clean and organize the data, identify patterns, and make predictions based on the analysis.