Quality control is essential in manufacturing to ensure products meet customer expectations and regulatory standards. AI vision systems improve manufacturing quality control by automating and streamlining the inspection process.

In this article, we’ll explore how AI vision systems detect and classify defects, their benefits, case studies of successful implementations, and considerations for businesses looking to invest in AI vision systems.

AI vision systems use computer vision technology and machine learning algorithms to automate visual inspections of products, parts, and processes. This helps manufacturers detect defects and other quality issues more quickly and accurately than traditional manual inspection methods.

AI vision systems have many applications in manufacturing; one of the most critical is quality control. Quality Control involves monitoring and evaluating different aspects of manufacturing to ensure products meet the desired standards. AI vision systems help provide reliable automated inspections. Manual inspections leave room for human error and delayed timelines.

Defect detection is one of the most common applications of AI vision systems in manufacturing. These systems detect and classify defects with high accuracy and speed, lowering the chances of faulty products reaching customers.

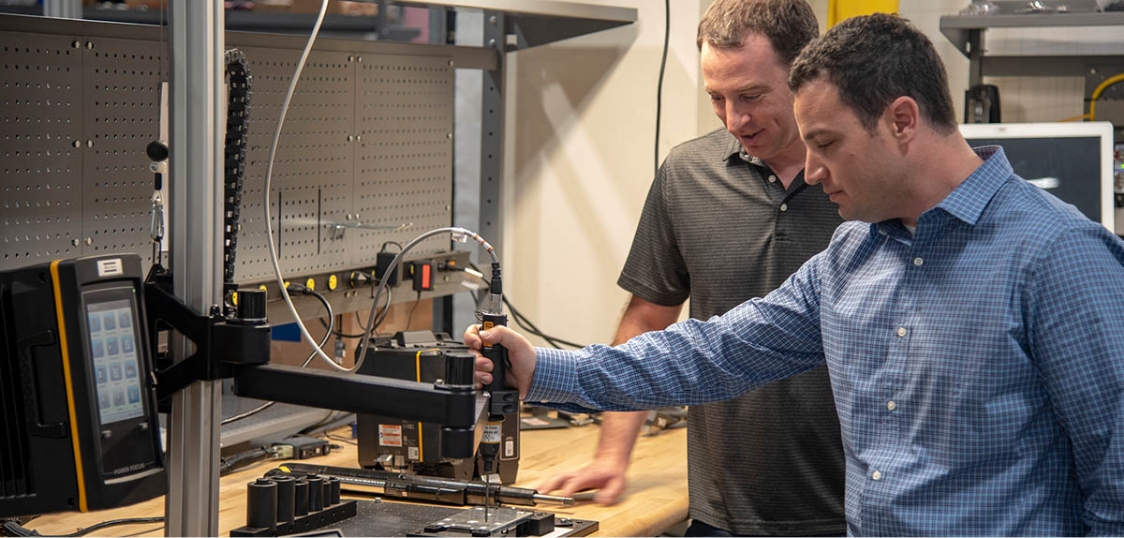

Robotic QC is another area where AI vision systems have been successfully applied. These systems help automate the inspection process. There’s no need for human intervention, and they minimize errors.

While other QC inspection methods fall short, Flexible Vision can successfully deploy across different assembly environments. Our clients witnessed great success when we were deployed in two key environments: Operator QC and Robotic Assembly QC.

Operator QC helps monitor and verify that the operator follows all critical work instructions.

Related: A Breakdown of Industry Uses of Flexible Vision

Here’s everything you need to know about how our AI machine vision software and hardware application works.

Detecting defects using AI vision systems involves a few steps. First, the system captures images of products or parts being inspected. Next, the system uses computer vision algorithms and machine learning techniques to identify defects. Finally, the system alerts operators to reject defective products.

Our machine vision solution has been used with multiple x-ray inspection systems to detect defects on the factory floor. Defects can be seen in soldering joints in printed circuit boards, cargo inspection, and missing components in the post-assembly stage.

Common defects detected using AI vision systems include cracks, chips, surface irregularities, missing or misaligned components, and incorrect assembly.

AI vision systems can classify defects in several ways, depending on the application and type of defect. One approach is to use machine learning algorithms to organize defects based on their visual characteristics, such as size, shape, and color. For example, a system might be trained to classify scratches as either minor or major based on their length and depth.

AI vision systems collect a wide range of data during the inspection process, including images of the product or part being inspected, metadata about the product or part (such as batch number or production line), and information about the inspection process itself (such as the time of day and the operator performing the inspection).

Data collected by AI vision systems help manufacturers identify trends in product quality over time, allowing them to improve their processes and reduce the likelihood of defects occurring in the future. Data can also be used to track the performance of individual operators or production lines.

Real-time data analysis allows manufacturers to identify quality issues as they occur and take corrective action more quickly. It helps manufacturers identify patterns in quality issues that may indicate a larger problem in the production process.

Interested in learning more? Book a consultation with us and take your production process to the next level.

One of the primary benefits of using AI vision systems for quality control is improved accuracy and efficiency in detecting defects. AI vision systems can detect defects that may be difficult for humans to see and can do so at a much faster rate than manual inspection.

AI vision systems help reduce human error and bias in the quality control process. Humans may overlook defects due to fatigue, distraction, or personal biases, whereas AI vision systems can consistently analyze images for defects.

AI vision systems also enhance production efficiency by streamlining the quality control process. Automated defect detection reduces the need for manual inspection. This helps improve overall productivity.

Ultimately, using AI vision systems for quality control increases product quality and customer satisfaction. By catching defects earlier in the production process, manufacturers reduce the likelihood of defective products reaching the end consumer. This improves overall customer satisfaction and reduces the risk of a negative brand reputation.

Maintaining the physical components used in manufacturing is crucial to prevent costly downtimes and machinery breakdowns. One solution to this problem is predictive maintenance, which uses machine learning and IoT devices to collect data on machinery and components through sensors.

Businesses save money in downtime by identifying signals and taking corrective actions before components break down. For instance, FANUC’s ZDT (Zero Down Time) software program uses AI vision to collect images from robots’ cameras. It sends them to the cloud for processing, helping to detect potential problems before they occur.

Pharmaceutical companies must ensure that they accurately count tablets or capsules before packaging. England-based Pharma Packaging Systems developed a solution that can be integrated into existing production lines or run as a lone unit to address this issue.

The solution uses AI vision to detect broken or partially formed tablets moving through the production line. Images of the tablets are taken and processed using specialized software that analyzes their color, length, width, and integrity.

Find out why businesses trust us for their quality control needs.

Investing in AI vision systems can be expensive, and businesses need to conduct a cost-benefit analysis to decide if the investment is worthwhile. The benefits of AI vision systems include improved accuracy in detecting defects, reduced human error and bias, enhanced production efficiency, and increased product quality and customer satisfaction.

Businesses need to weigh these benefits against the costs of implementing the system, including hardware, software, and integration costs.

AI vision systems need to be integrated with existing systems and equipment to work effectively. Businesses must consider whether their current systems and equipment can be integrated with AI vision systems or if new hardware and software must be purchased.

Implementing AI vision systems requires staff training and adoption. Your employees need training to use the system effectively.

AI vision systems collect and analyze sensitive data, and businesses must ensure their systems are secure and comply with privacy regulations. This includes ensuring that data is encrypted during transmission and storage, limiting access to data, and implementing access controls.

AI vision systems are constantly evolving, and businesses must consider future developments and trends when investing in the technology. This includes developments in machine learning algorithms, improvements in hardware and software, and new applications for AI vision systems in manufacturing quality control

In conclusion, AI vision systems are revolutionizing the manufacturing industry by providing accurate and efficient quality control solutions. By detecting defects, analyzing data, and enhancing production efficiency, these systems help businesses improve their bottom line and increase customer satisfaction. As technology continues to develop, the future outlook of AI vision systems in manufacturing quality control looks promising.

At Flexible Vision, our executive team comes from 20+ years in the automation and vision world and has experienced the challenges of traditional vision systems on production lines. With an understanding of the industry’s needs, we’re here to help you make quality control a breeze.

Schedule a live demo with us to learn more.

AI vision systems improve production efficiency in manufacturing quality control by streamlining the visual inspection process. This reduces the time and resources required for manual inspection and frees employees to focus on other tasks.

AI vision systems collect and analyze sensitive data, so their systems must be secure and comply with privacy regulations. This includes ensuring that data is encrypted during transmission and storage, limiting access to data, and implementing access controls.

AI vision systems are more accurate and efficient than traditional quality control methods. AI vision systems detect defects faster and more accurately than humans, improving quality control.