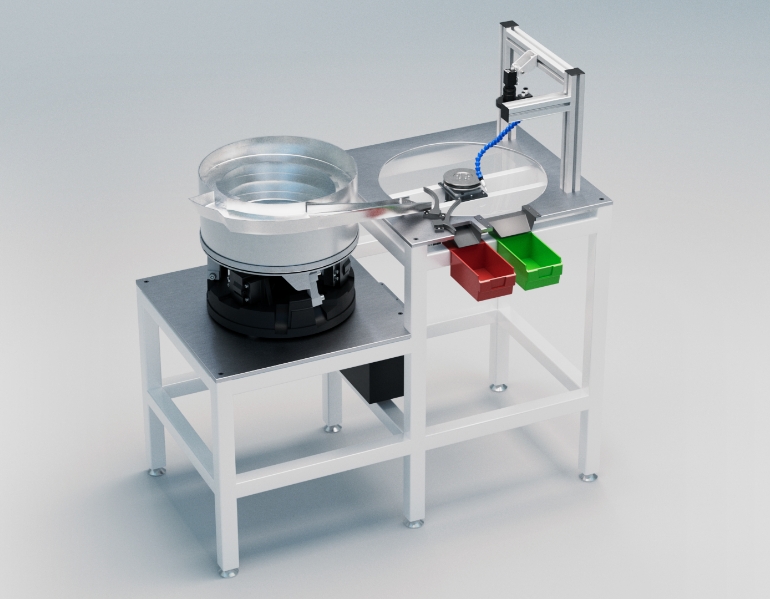

QC inspections play a key role in maintaining the factory floor. However, they must be rapid, effective and accurate. Manual parcel inspection leaves room for human error and delayed timelines which can negatively influence the supply chain.

Our AI-based machine vision solution helps you exceed the highest standard of efficiency, inventory control and regulatory requirements.

The advancement of technology is transforming the future of QC inspections and inventory management, allowing businesses to take their factory workflow to the next level in up-and-coming ways. With Flexible Vision, you can ensure all inspections are completed on time with minimal errors.

Since our software has been deployed across multiple environments, we have witnessed first-hand how adaptable and methodical new technology is on the factory floor.

Our machine vision solution can solve problems that previous operations couldn’t. We work alongside you to create systems and processes that suit your inspection needs.

QC detection, in the box, before shipment

Inventory management and adjudication

Image archiving and search to query specific items and shipments for parcel verification

Accurate operation across multiple lighting environments

If you want to learn more about parcel inspection applications, reach out to speak to one of our engineers here at Flexible Vision. Contact us today for help with your specific needs.

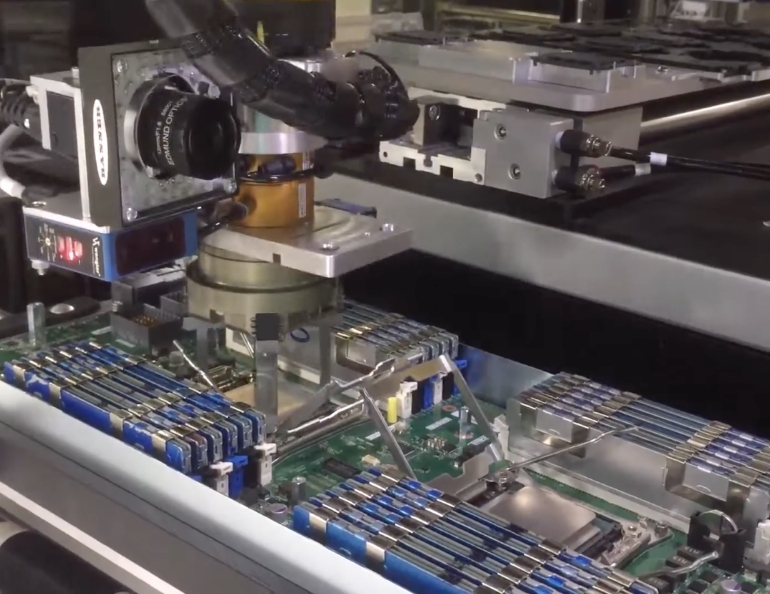

Our machine vision solution has been used with multiple x-ray inspection systems to detect defects on the factory floor. In industrial use cases, defects can be detected in soldering joints in printed circuit boards, cargo inspection, and missing components in the post-assembly stage.

Since Flexible Vision integrates seamlessly with most x-ray inspection hardware on the market today, you can reduce the costs of deploying an additional system to ensure compatibility.

If you have existing hardware, our team can assist you with the integration process to ensure everything runs smoothly. If you need to implement a new x-ray inspection application, we can consult you in choosing the proper hardware for your needs.

If you are ready to get started or have any questions about the integration process, contact one of our engineers today. We are ready to assist you with any of your system needs.

While many other QC inspection methods fall short, Flexible Vision is capable of successful deployment across a variety of assembly environments. In cases where meticulous guidelines and quality needs are expected, we bring expert assistance to complex processes.

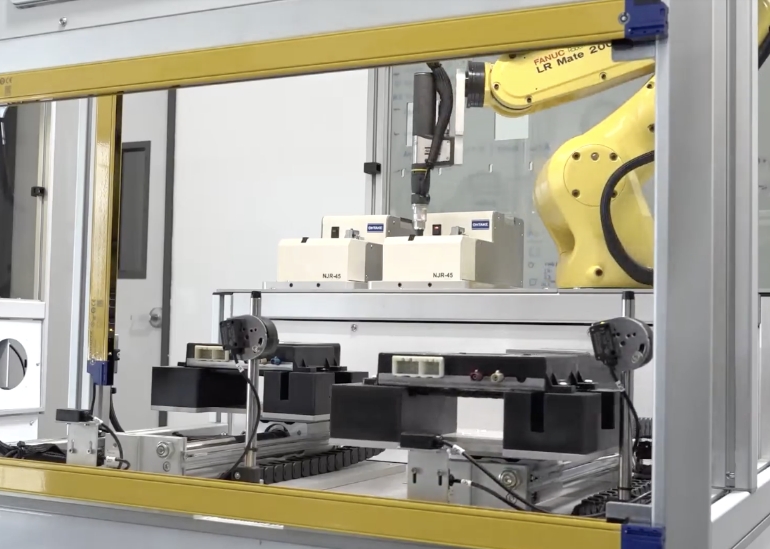

Our clients witnessed great success when Flexible Vision was deployed in two key environments: Operator QC and Robotic Assembly QC.

Flexible Vision can be used at assembly workstations to monitor and verify that the operator follows all critical work instructions. In this case, you can ensure that the final assembly meets all engineering requirements.

By integrating Flexible Vision, you are able to maintain exceptional quality control and efficiency on the factory floor. Our systems also work hand in hand with augmented assembly instructions, helping improve any manual manufacturing process.

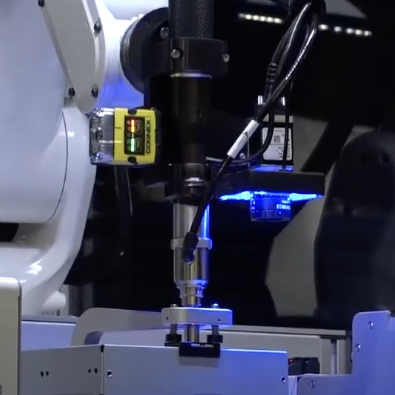

Flexible Vision’s inspection system integrates seamlessly with industrial robots and PLCs, optimizing the overall capability of your processes. Our technology works alongside your systems to inspect every assembly process step.

As a result, processes are able to remain dynamic while constantly adjusting to your quality control requirements.

For example, Flexible Vision has been deployed in various assembly environments where robotic systems must adapt to product variation. Validating upstream operations prior to robotic assembly is critical.

Our system allows your automated system to see cosmetic defects, misplaced gaskets, circuit board placement, threadlock compound detection, thermal paste compound volume, bent CPU pins and more.

If you are interested in optimizing your operator or robotic quality control, reach out to one of our engineers today. We are prepared to help you integrate Flexible Vision into your current technology and processes.

Our machine-learning solution is scalable and adaptable across multiple nodes. It is common for our customers to have several lines running similar products across multiple factory sites.

Teams can share effective AI models across these sites and centrally collect image data. Flexible Vision is compatible with traditional vision systems that may be required for your factory processes. You can easily add AI and traceability capabilities to these existing cameras.

The key advantage of working with Flexible Vision is enhanced accuracy and precision across multiple lighting environments. Since our systems are compatible with different hardware types, your factory can save significant capital expenditure in deploying additional systems.

If you are ready to learn more about how Flexible Vision can integrate into your factory floor operations, reach out to one of our engineers today. We are prepared to help you every step of the way with the most efficient, affordable assembly inspection solutions.